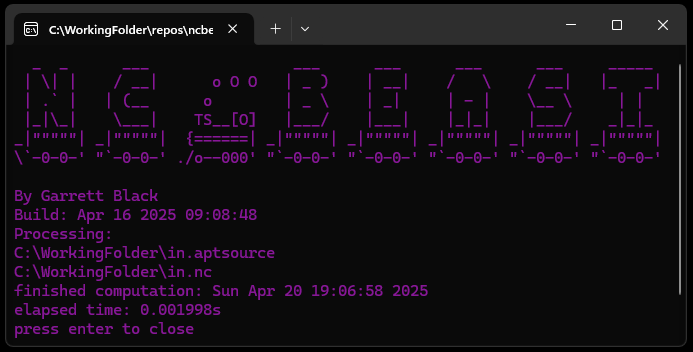

Information

machines.csv

⬆️ this is a settings file.

inside is how you configure the processing for your machine.

custom words can be added, output is highly customizable.

Kinematics

0=XYZ axes only

411=XYZ with A axis rotary

412=XYZ with B axis rotary

511=XYZ with A and B axes in the head

512=XYZ with A and C axes in the head

513=XYZ with B and C axes in the head

5131=XYZ with non-orthagonal B and C axes in the head

521=XYZ with A and B axes trunnion table style

522=XYZ with A and C axes trunnion table style

523=XYZ with B and C axes trunnion table style

5231=XYZ with non-orthagonal B and C axes on the table

6=XYZ with ABC Euler angles positioning output for 6DOF robot

Expected apt words below:

using the provided CatiaV5-3DX.pptable or Fusion360.cps will make everything run smoothly.

MACHIN/

signals which settings to use in the machines.csv file.

PARTNO

marks the beginning of the header and tool list.

ORIGIN/G54 or ORIGIN/G54,1 P123

signals the Work Coordinate Offset to use. (example: “G54” and “G54.1 P123”)

ROTABL/A,-45.0

manual control over A, B, or C rotary axis absolute position. (ROTHED, and ROTATE work the same.)

CLAMP/(A,B,C),(ON,OFF)

signals to the post the desired condition of the axis clamp. This is a modal command that when toggled “ON” the clamp will stay clamped unless a rotary move is commanded. In the event of a rotary move, the clamp will be turned off until rotary move finishes, and then clamp will be turned on again.

SPINDL/ORIENT

spindle vector tracking toggled on, SPINDL/OFF cancels this output.

MODE/INCR,(ON,OFF)

incremental motion output.

MODE/POLAR,(OFF,constraintLineAng),tolerance

example: MODE/POLAR,OFF MODE/POLAR,45,.001 when tool axis is aligned with rotary axis: constrain XY motion along a line of which the first value, ‘45’ dictates the angle relative to X axis. rotate the rotary axis (typically C axis) to achieve desired motion. the second value is the allowed deviation tolerance from the programmed path. if the specified tolerance is violated, a new point will be generated on the path, if an arc or helical motion is programmed, the INTOL tolerance will be used for that motion.

MODE/RAPTO,(ON,OFF)

output rapid motion with G0, default is set in machine settings. when turned OFF, max feedrate is output for rapid motion.

MODE/ROUND,(OFF,safeCornerLoss),minCornerRadius

add arcs at every corner while in rapid mode. input parameters are safeCornerLoss which is the allowed distance from corner that an arc can begin or end. and the second parameter minCornerRadius which specifies minimum corner radius to add an arc too. (some moves are too short for any arc benefit) MODE/RAPTO must be OFF for this to work.

MODE/CIRCUL,(OFF,tolerance)

arc fitting, use OFF to turn off or enter a value like MODE/CIRCUL,0.005 to create arcs with a programmed path deviation allowance of .005.

MODE/LINTOL,(OFF,tolerance)

colinear point removal, use OFF to turn off or enter a value like MODE/LINTOL,0.0002 to remove the middle point in any set of 3 points that are in a line within .0002.

SET/HEAD,aRot,cRot,pivotLength

enables angle head offsets on output, SET/HEAD,OFF cancels this.

aRot = the degrees the tool vector is rotated about the X axis.

cRot = the degrees the tool vector is rotated about the Z axis.

example:SET/HEAD,90,90,4.5

if looking down on table from above: Example would be a 90 head with a 4.5 inch distance from spindle centerline to tooltip. With the tip pointing West.